Benefits of a calibration management software

An automated calibration management software offers a variety of benefits to businesses. These range from reduced costs and increased efficiency to greater control over equipment maintenance and management.

Listed below are some of the most highlighted benefits that a calibration management solution has to offer.

1) Automated and streamlined workflows

A CMS tool offers automated planning that serves to reduce the administrative and managerial load. The software helps streamline workflows and assist the calibration managers who are tasked with managing calibration intervals. Their purpose is to make a well-researched and qualified recommendation. Equipment engineers are also given the

ability to optimize calibration intervals using the software’s ‘History Trend’ function.

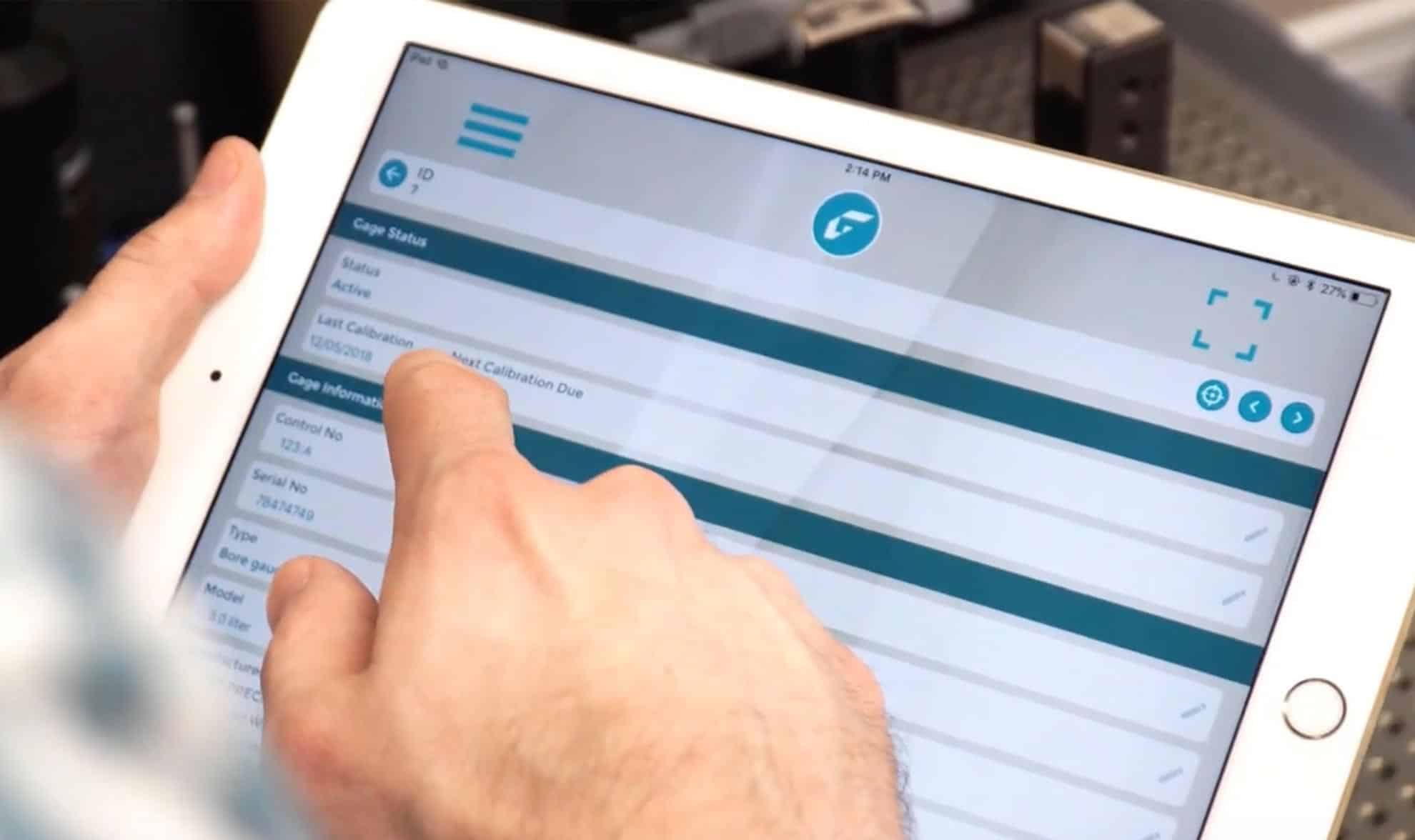

In addition to this, manual procedures are replaced with automated and validated processes. Equipment managers no longer require pens and paper. Calibration instructions are created using the software to guide engineers through the calibration process. These instructions can also be downloaded to a technician’s handheld documenting calibrator while he is on the field.

2) Improved efficiency

As the entire calibration process becomes more streamlined and automated, plant efficiencies also improve. As the manual procedures are replaced with automated ones, businesses can save time in a lot of labor-intensive calibration activities. Engineers are freed up to perform more strategic analysis or other important value-added activities.

3) Cost reduction

Implementing a software-based calibration management helps businesses reduce the overall costs. These savings come from the now paperless calibration process, with no manual documentation procedures. Moreover, a CMS solution enables faster, easier and more accurate analysis of calibration records and identifying historical trends. Plants can, therefore, reduce costs and optimize calibration intervals.

4) Performance management

A calibration management program can help equipment managers keep track of Key Performance Indicators (KPIs) in real-time, while also giving them a detailed view of operations. Performance of the installed equipment and resources can be analyzed across the entire organization.

5) Compliance with regulations and standards

Regulatory organizations and standards such as FDA and ISO place demanding requirements on calibration data records. A calibration management software has many functions that help in meeting these requirements. A CMS solution helps track compliance with calibration timeliness, according to FDA and ISO. It makes sure that the guidelines and standards are met accordingly.

6) Maintain records and history of use and calibration

Procedures and calibration strategies are planned. All calibration assets are managed automatically by the calibration management software. The program also maintains a device’s position and calibrator databases while also setting up automatic alerts for scheduled calibrations. The software also automates report generation and centralizes calibration data storage.

7) Equipment longevity

Planning and keeping track of equipment maintenance can be a really tiring task. A lot of resources, both time and money, are invested in ensuring equipment longevity. A CMS solution can automatically calculate an item’s due date for calibration and maintenance according to the user-defined intervals.

A calibration management software gives equipment managers the ability to define how they want the due date calculated and set the calibration frequency to any number days, months or years. In addition to this, downtime will be greatly reduced as your equipment is calibrated and maintained on schedule, saving your business both time and money.