What constitutes a calibration management process?

Before we go further into the need of having a calibration management solution, its features, and benefits – it is important to consider the typical calibration management tasks that businesses have to undertake. Listed below are some steps that constitute a typical calibration management process:

1) Identification, classification, and planning

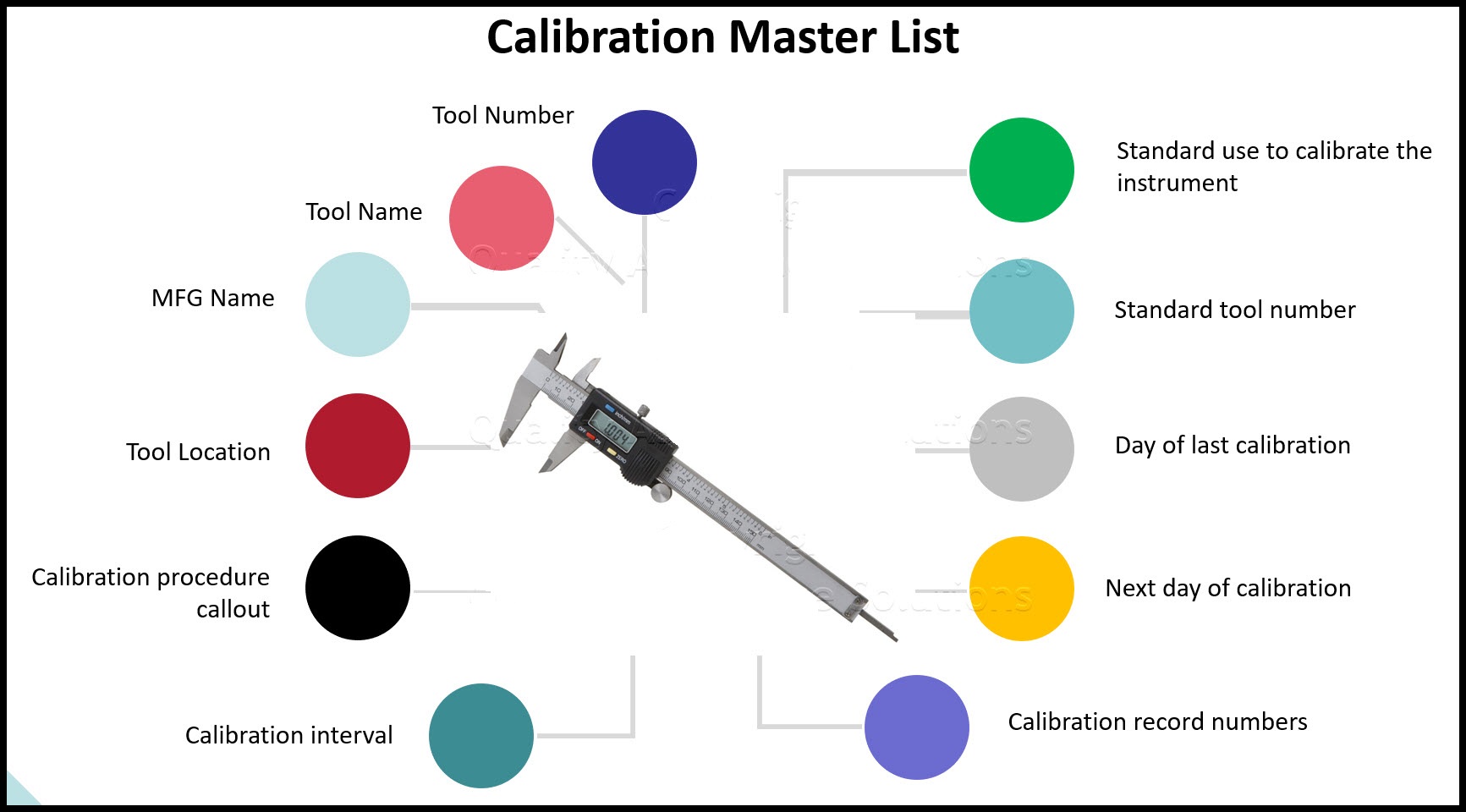

Firstly, the instruments and measurement devices that a business owns are listed. They are then classified as either ‘critical’ or ‘non-critical’ devices or their calibration range and required tolerances are identified. Decisions are then made regarding the calibration interval for each instrument. Finally, an equipment manager must identify current calibration statuses for all instruments across the organization.

2) Organization

The calibration staff needs to be organized. They must be trained in using the chosen tools and carrying out the scheduled calibration tasks.

3) Deciding calibration periods

Calibrations are usually done:

- Before and after a major critical measuring project

- After the instrument took a hit

- According to the requirement of a particular job

- On a monthly, quarterly, biannual or annual basis

4) Execution

Calibration activities are then executed by the calibration staff who must follow the appropriate instructions, which would include any associated safety procedures.

5) Documentation

The process and the calibrations need to be recorded and documented on a regular basis. This is done to maintain an accurate record on calibration.

6) Analysis

Based on the documented calibration results, equipment managers then have to analyze the data to see if any corrective action needs to be taken.